QLEAP KMR Maintenance Management System

Request

DEMO presentation

QLEAP KMR is a modern system for optimizing and managing maintenance intended for planning and organizing the flow of maintenance activities of machines and equipment in a factory, company or office building.

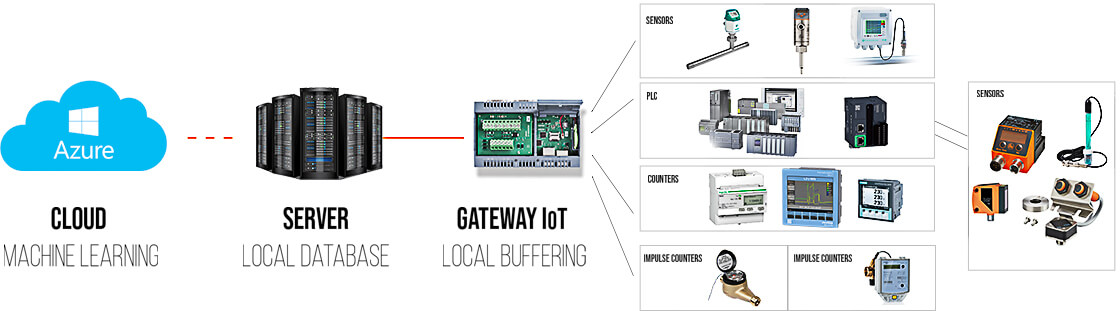

QLEAP KMR integrates IoT (Internet of Things) technologies and can automatically retrieve useful information from equipment or machinery for maintenance management, such as: operating time, vibrations, temperature, level, flow or concentration.

How it works

QLEAP KMR IoT

The sensors mounted on the equipment capture and process data in QLEAP KMR, then the information is stored and analyzed in the context of the recordings made. This process creates valuable opportunities. First of all, technicians can schedule their interventions based on predictive maintenance analyzes and, thus, they can repair a piece of equipment before it goes into downtime. Second, even if an unexpected failure occurs, the maintenance team will be informed immediately through an alarm system.

Corrective/ accidental maintenance

Preventive/ planned maintenance

Alarms and notifications

Predictive maintenance

Ticketing – work tasks assignment

Configurable roles and persmissions

IoT module – real-time monitoring

Spare parts and accessories management

Machinery and equipment management

Diversified reports

Deployments of maintenance management system

Clients

Measurement and monitoring of KPI

- Multiple work points setup

- User access control: roles, rights, access areas

- Nomenclatures: revision type, equipment and consumables categories, service providers, working procedures

- Custom alerts and notifications setup

- Import-export Excel data

- Work tasks assignment (tickets, requests)

- Acces la resurse: manual de service, istoric interventii, situatii similare etc.

- Real-time alerts, notifications, and information

- Mobility - web interface (laptop, tablet, phone)

- Reports on workloads assigned to technicians

- Reports on materials (top costs or uses)

- Reports on equipment (costs, overhauls, number of overhauls)

- Reports on revisions and interventions (top costs, delayed or planned)

- Necessary materials planning

- Cost control

- Stock control

- Stock control: minimum threshold alert, stock record in multiple work points

- Cost control

- Planning the materials needed in the interventions

- Consumables required

- Operating time

- Vibrations

- Temperature

- Level

- Flow

- Concentration

Benefits

Configure the list of existing equipment in the factory with all the necessary information (technical specifications, images and technical documents)

Customize the maintenance plan

Add tickets / report problems to the maintenance team related to the operation of the machine

Access to the events and interventions history

Access to reports and statistics (KPIs) and to machine operators activity reports

View in real time of the working order of the equipment by viewing the values sent from the sensors

Validates the tickets that appear in the system, signaled by the machine operators, depending on their type: electrical, mechanical, technological failure, etc.

Monitor and complete the daily / periodic maintenance assigned to the machine

Presentation

materials

You always have the presentation of the maintenance management at a click

Smart Maintenance or

QLEAP KMR IoT

QLEAP KMR Industrial IoT can automatically retrieve data from sensors and devices connected to the network, all of which represent a new stage of the automation concept. This system allows the collection of data, their sharing in a central server and the analysis of the results in order to obtain specific reports regarding the necessary activities that have in mind preventive and predictive maintenance.

More information about the QLEAP KMR IoT system

This contributes to:

- Analysis of complex actions that have not been within eyeshot so far

- Increasing efficiency and reaction time in production

- Useful resource management

- Increasing employee productivity due to obtaining information from several devices that communicate with each other and download their interconnected data in a central system

- Improving the quality and quantity of data collected, as well as the reliability of assets and streamlining of maintenance resources

- Display the collected data in an easy-to-read manner through dashboards and charts

- Secure data sharing with key staff outside the organization. When the maintenance team and external technical experts have access to common data, they can solve problems faster and make changes to help reduce downtime

Useful information retrieved through

IoT

Equipment operating time

The counting of the operating time of the machinery/equipment offers an optimal control of the wear and tear generated over time by planning predictive and preventive maintenance according to the manufacturer's indications. It separates the idle running time of the machine from the working time, highlighting information to the second about the type (in case the operator abuses the machine) and the time (the machine was started for 8 hours, but it actually worked for two hours) of using the machine.

Vibrations

Any equipment shows certain symptoms before it breaks down, and the vibration level is the main parameter by which the degree of wear can be identified. The main types of defects that can be detected: imbalance of the rotating parts; poor fixation; bearing defect; misalignment; defect, gear wear; shocks, peaks; bearing; cavities, pump flow problems.

Temperature

Temperature is the parameter by which the quality of the oil in the installations, engine flaw, electrical panel flaw, etc. can be deduced. When temperature value goes out of the set tolerance range, it is sent an alert that allows the technician to prevent a serious malfunction.

Level

Monitoring level to detect fluid shortages or overflow will help prevent damage to gears, installations or inadequate set ups.

Pressure

The appropriate control of the pressure will help you to timely detect the losses on the route to the compressed air installation and, thus, to maintain the constant performance of the equipment and avoid financial losses (through a 1 mm hole in a compressed air network with the pressure of 7 bar, losses of over 6 MWh/year can be reached).

Targeted

business directions

Industrial

producers

Service

companies

Universities and

schools

Office

Public

administration

Hospitals,

polyclinics

Schedule an online presentation

Main

features

Say goodbye to papers, cluttered files or maintenance and interventions files! Maintenance management is now extremely simple, fast and effective. You have access at any time to the information of interest, to be able to make quick decisions efficiently.

Ensure continuous operation of equipment and reduce downtime. Prevent the occurrence of accidental failures, reduce the wear of dynamic and static components. Reduce the total maintenance costs by monitoring the technical condition of the equipment and their behavior over time, in order to determine the work required from the first planned repair.

The application has the ability to warn you before a machine breaks down. Everything is done by integrating IoT technologies that automatically take useful information from equipment/machinery about their operating status.

You have an overview of the maintenance activity, as well as specific information to each action implemented or planned. You have full control over the whole activity (equipment, materials, people in charge) and over the costs involved.

Complete database with all the equipment subjected to maintenance / reparation. Add here all the equipment with the following details: name, inventory number, location, warranty period, commissioning date, operating meter, images, additional data of interest.

Planning and maintenance / interventions management for each equipment: type of overhaul / maintenance, responsible technician / supplier, date, alert, status, diagnosis, tasks, used materials, associated documents, costs.

Real-time access to updated information about the materials needed for maintenance / repairs: name, manufacturer, existing stock, price. Material lists can be imported and exported from Excel files.

Reduce response time by assigning work tasks to technicians (tickets/requests), evaluate staff and prepare activity reports. Distribute the tasks in a balanced way and effectively monitor the activities and productivity of the employees.

The machines registered in the QLEAP KMR system are associated with a unique QR code, which once scanned allows the technicians logged in the system to start solving the tickets assigned to each machine. Thus, the activity of the employees and the status of the tickets are recorded.

In addition to ticket management, the simple scan of the QR code gives authorized employees instant access to information about the machine (technical specifications, maintenance history, operating hours, revision status, user manuals and any other material necessary for carrying out the activity).

Archive in the application any material that you consider useful for the maintenance activity - manuals for the use of equipment, service manuals, minutes, etc. You have quick and easy access to the history of revisions and interventions for each piece of equipment. Thus, you can easily establish the necessary materials and works depending on the situations from the previous repairs.

There can be generated 10 types of reports for:

- materials: top uses, top costs, material usage details

- equipment: top number of revisions, top revision costs, details of equipment revisions

- revisions/interventions: top costs, delayed revisions/interventions, upcoming revisions according to the operation meter, similar situations

- tasks assigned to technicians: tickets and requests, equipment user manuals, service manuals, minutes, history of revisions and interventions for each piece of equipment

Perform analyses and make decisions based on specific reports generated from the application, extremely useful information for: management, economic department and maintenance department.

- validate the quality of work activities; you can quickly detect equipment with frequent failures, abusive or irrelevant actions can be identified, the areas that give the best results and which are the areas where losses are recorded

- manage inventory and budget reporting as needed

- you can find out information related to the more efficient or weaker equipment depending on the ones that produce the most maintenance expenses (top expenses, top uses, top revisions, etc.)

- optimize employee activity and production using forecasts

- analyze the impact of the implemented measures

- prove the efficiency in management and production of the company to attract new contracts

You are informed in good time about the activity carried out. Quick interventions to correct irregularities. The application has a web interface that allows you to access information permanently from anywhere there is internet, regardless of whether you use a computer, tablet or mobile phone.

Simplify the process and increase the speed of work interventions. You have real-time access to information/decisions, you are sure that accurate and detailed information is sent to the right people, at the right time.