Servicii termografiere

Solicitati

Oferta

Vă rugam să ne contactați. Pentru orice întrebări, comentarii sau clarificări, vă stam la dispoziție

Verificare instalatii electrice prin

termografie

Termografia este o tehnica non-invaziva de imagistica termica care utilizeaza camere termice speciale pentru a detecta si a vizualiza variatiile de temperatura ale obiectelor si suprafetelor. Aceasta tehnica permite identificarea rapida a disfunctiilor termice, defectelor de izolatie, pierderilor de caldura, conexiunilor slabe si a altor anomalii termice care pot duce la pierderi de energie si deteriorarea echipamentelor.

Implementari de succes

Referinte

Serviciile de termografiere sau termoviziune implica utilizarea unei camere termice sau a unei camere termografice pentru a masura si a inregistra temperaturile obiectelor si suprafetelor. Aceasta tehnica se bazeaza pe principiul ca obiectele cu temperaturi diferite emit radiatii infrarosii in functie de temperatura lor. Termografierea este utilizata in diverse domenii, inclusiv in domeniul medical, constructiilor, mentenantei industriale, energiei, securitatii, etc.

Termografierea sau termoviziunea

Beneficii

Termografierea pentru mentenanta industriala este o tehnica utilizata pentru a identifica si a evalua starea echipamentelor si a masinilor industriale prin masurarea si analizarea variatiilor de temperatura. Aceasta metoda se bazeaza pe faptul ca majoritatea problemelor tehnice, cum ar fi supraincalzirea, uzura, defectele sau blocarile, se manifesta prin schimbari in temperatura.

Iata cum este folosita termografierea in mentenanta industriala:

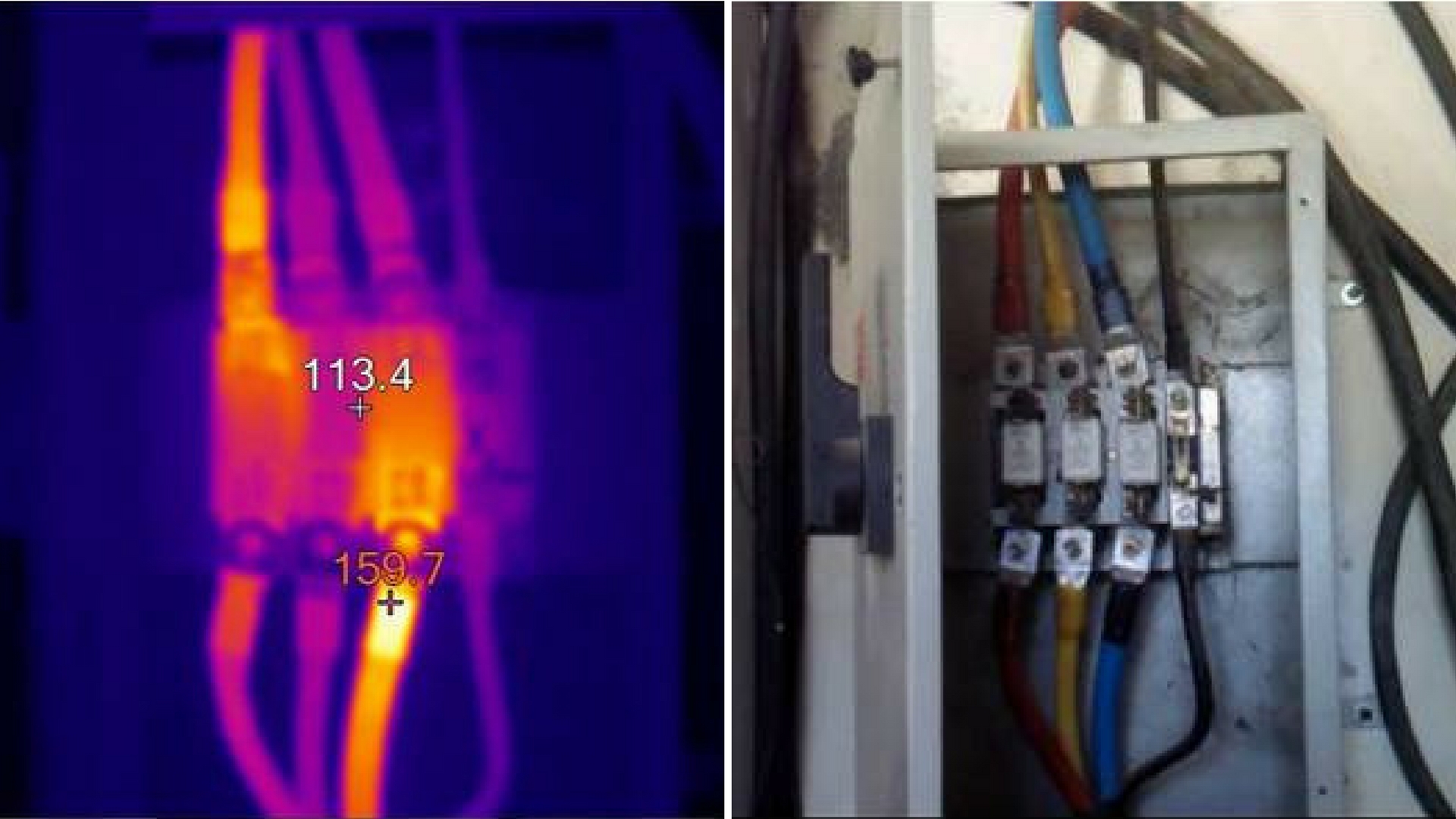

Detectarea problemelor incipiente: Termografierea permite detectarea problemelor in stadii incipiente, inainte ca acestea sa devina defecte majore. Prin identificarea si remedierea problemelor la timp, se minimizeaza costurile de reparatii si se reduce timpul de nefunctionare al echipamentului.

Monitorizarea continua a temperaturii: Termografierea poate fi utilizata pentru monitorizarea continua a temperaturii in timp real a echipamentelor si masinilor critice. Acest lucru permite identificarea imediata a oricaror variatii anormale de temperatura, ceea ce poate indica potentiale probleme sau defectiuni iminente.

Evaluarea starii echipamentului: Termografierea poate oferi informatii detaliate cu privire la starea echipamentului si a componentelor sale. Astfel, se poate evalua gradul de uzura, integritatea structurii si performanta generala a echipamentului.

Imbunatatirea eficientei energetice: Termografierea poate ajuta la identificarea punctelor de pierdere de energie in instalatiile industriale, precum si la evaluarea eficientei sistemelor de izolare termica. Prin remedierea acestor probleme, se poate reduce consumul de energie si se pot realiza economii semnificative.

Programarea intretinerii preventive: Pe baza datelor furnizate de termografie, se poate dezvolta un program eficient de intretinere preventiva. Aceasta inseamna ca reparatiile si inlocuirile pot fi programate in avans, in loc sa fie efectuate in urma unor defectiuni neasteptate.

Imbunatatirea securitatii: Identificarea si remedierea potentialelor probleme si defectiuni din instalatiile si tablourile electrice contribuie la cresterea sigurantei locului de munca si a sistemului electric in general, reducand riscul de incendii, deteriorari ale echipamentelor sau alte incidente.

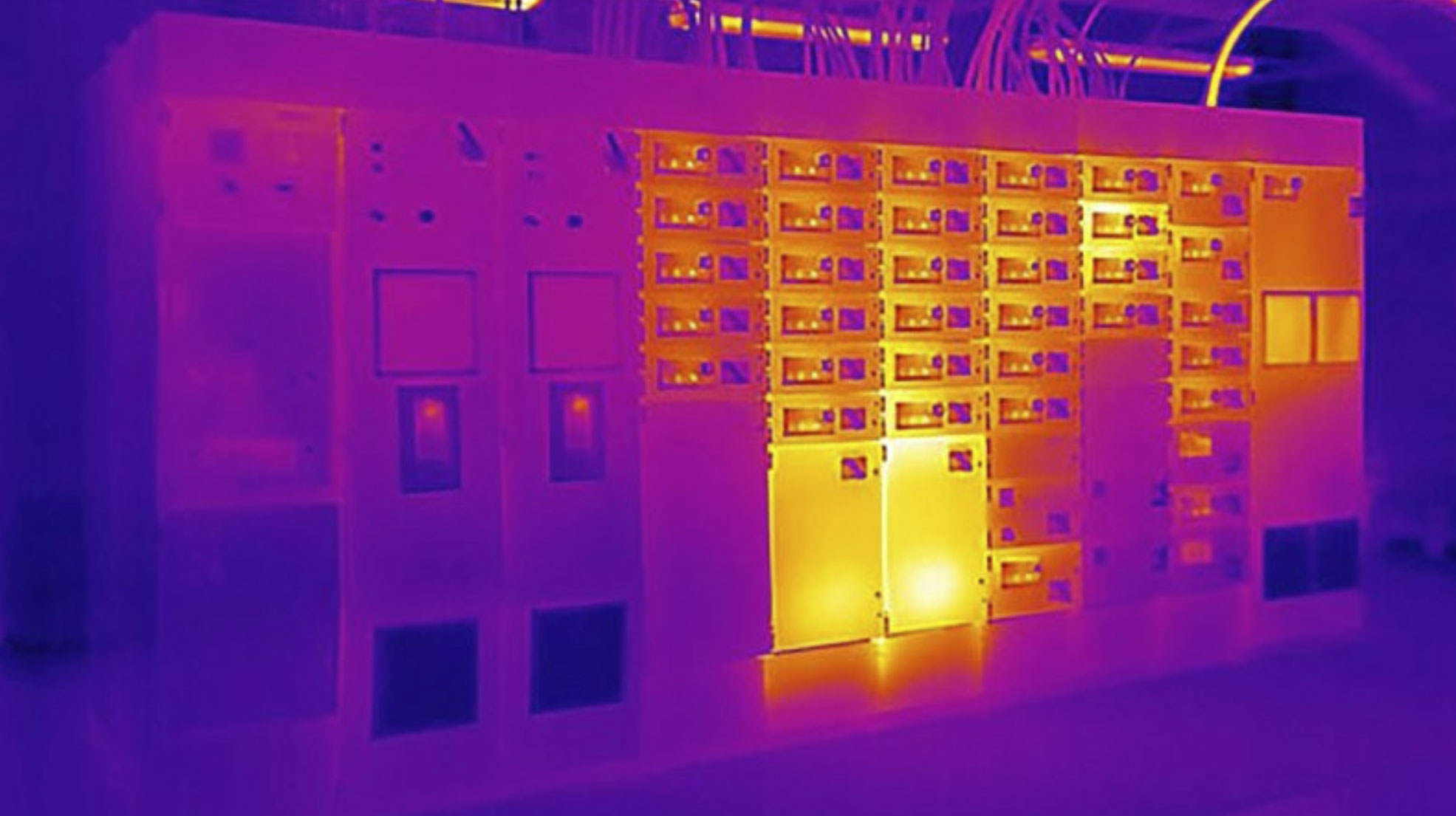

Termografierea instalatiilor si a tablourilor electrice

Servicii

termografiere

- Termografiere electrica: Detectarea conexiunilor slabe, a supraincalzirilor si a altor anomalii termice in echipamente electrice si sisteme de distributie.

- Termografiere mecanica: Identificarea supraincalzirilor si a disfunctiilor termice in componente mecanice, utilaje si instalatii industriale.

- Termografiere in procese industriale: Monitorizarea si evaluarea temperaturilor in timp real in procesele industriale pentru a asigura functionarea optima a echipamentelor si a preveni defectarile.

Etapele unei termografieri realizate de

Quartz Matrix

Procesul de termografie implica mai multe etape care trebuie urmate pentru a asigura o inspectie completa si precisa. Iata care sunt aceste etape:

Pregatirea: In aceasta etapa, este important o pregatire corespunzatoare a echipamentului si a mediului de lucru. Acest lucru poate include calibrarea camerei termice, asigurarea ca temperatura si umiditatea ambientala sunt adecvate pentru obtinerea unor imagini clare si precise si verificarea functionarii corecte a echipamentului.

Planificarea: Inainte de a incepe termografia, este esential sa se planifice si sa se stabileasca obiectivele si scopul inspectiei. Aceasta poate include determinarea zonei sau a echipamentului care urmeaza sa fie inspectat, precum si identificarea problemelor sau defectiunilor potentiale care trebuie sa fie cautate.

Inspectia vizuala: Inainte de a utiliza camera termica, este important sa se efectueze o inspectie vizuala a echipamentului sau a zonei care urmeaza sa fie scanate termic. Aceasta poate ajuta la identificarea problemelor evidente, cum ar fi conexiuni slabe, componente deteriorate sau alte defectiuni vizibile.

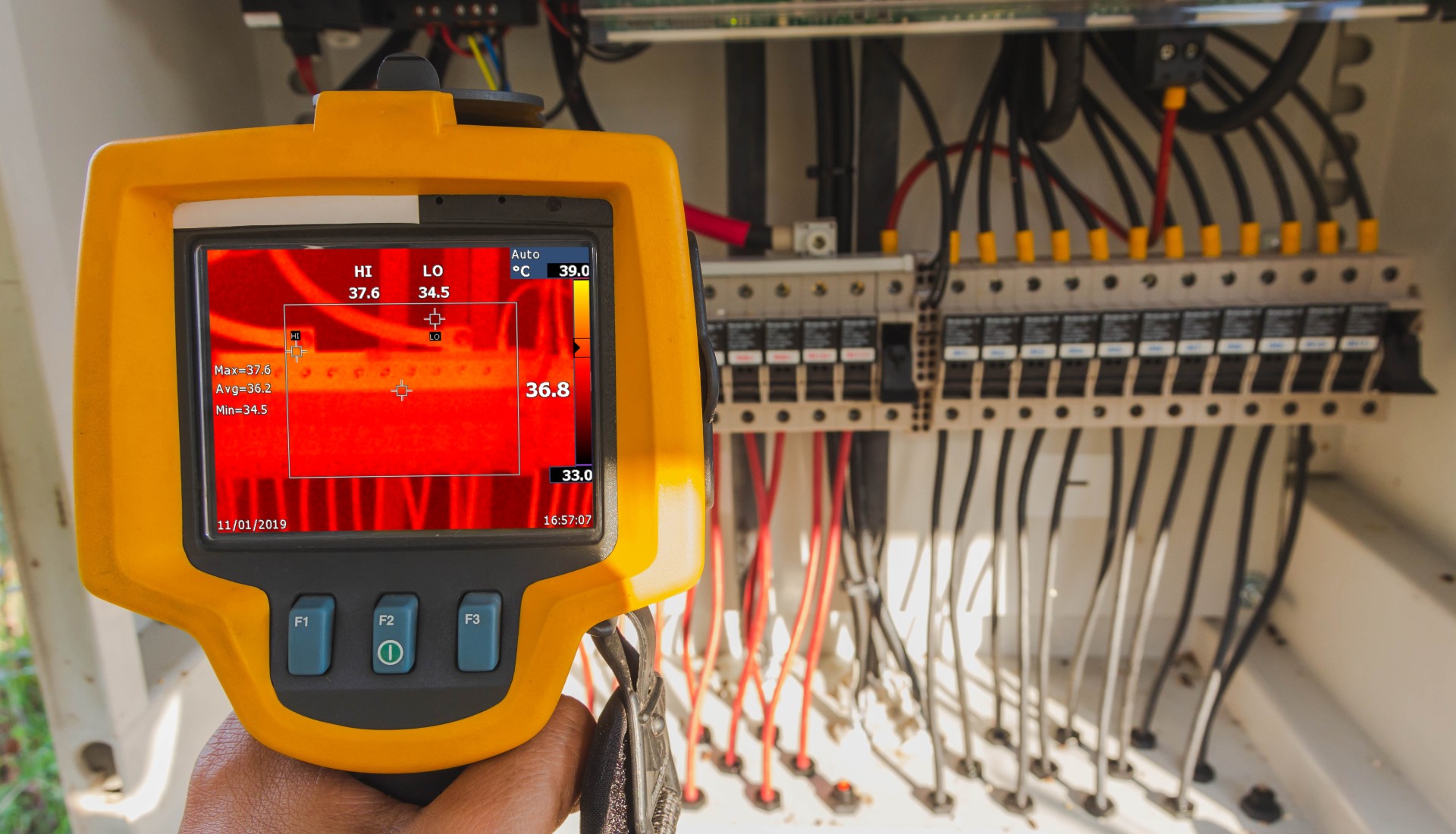

Scanare termica: In aceasta etapa, se utilizeaza camera termica pentru a obtine imagini termice ale zonei sau echipamentului inspectat. Operatorul camerei termice scaneaza suprafata cu atentie, capturand imagini termice ale tuturor obiectelor si componentelor relevante.

Analiza imaginilor termice: Dupa ce au fost obtinute imaginile termice, urmeaza etapa de analiza a acestora. Operatorul examineaza imaginile pentru a identifica variatii anormale de temperatura, puncte fierbinti sau alte anomalii care ar putea indica probleme sau defectiuni.

Interpretarea rezultatelor: In aceasta etapa, operatorul interpreteaza rezultatele termografiei si determina natura si gravitatea oricaror probleme sau defectiuni identificate. Acest lucru poate implica compararea imaginilor termice cu datele de referinta, evaluarea conditiei echipamentului si recomandarea actiunilor corective necesare.

Raportare: In final, rezultatele termografiei sunt documentate intr-un raport scris. Acest raport poate include imagini termice relevante, interpretarea rezultatelor, recomandari pentru remedierea problemelor identificate si alte informatii relevante.

Urmarirea si intretinerea continua: In unele cazuri, termografia poate fi parte a unui program de monitorizare continua sau de intretinere preventiva. Urmarirea in timp poate fi importanta pentru a evalua evolutia conditiei echipamentului si pentru a detecta eventuale probleme care pot aparea in viitor.

De ce

Quartz Matrix

Echipa noastra de tehnicieni certificati are o vasta experienta in domeniul auditului energetic si al termografiei si foloseste cele mai recente tehnologii si metode pentru a oferi rezultate precise, sigure si fezabile.

Furnizam rapoarte elaborate si interpretari profesionale ale imaginilor termice, alaturi de recomandari optime pentru remedierea problemelor identificate.

Ne adaptam cerintelor si nevoilor fiecarui client si oferim solutii personalizate pentru a asigura fiabilitatea si conformitatea solutiilor propuse.

Suntem autorizati de catre Autoritatea Nationala de Reglementare in Domeniul Energiei (ANRE), garantand astfel conformitatea si calitatea serviciilor noastre in domeniul energetic.

Scaderea costurilor cu asigurarea prin

Termografiere

Utilizarea serviciilor de termografie poate contribui la reducerea riscurilor asociate proprietatii si activitatii unei companii, ceea ce poate conduce la reduceri ale costurilor de asigurare pe termen lung. Este important de mentionat ca impactul exact asupra costurilor de asigurare poate varia in functie de contextul specific al fiecarei companii si de politicile individuale ale furnizorilor de asigurari, prin:

Prevenirea incendiilor: Termografia poate identifica punctele fierbinti sau alte anomalii termice care pot reprezenta riscuri de incendiu in cladiri, instalatii industriale sau alte tipuri de proprietati. Identificarea acestor riscuri si luarea masurilor preventive pot reduce probabilitatea producerii unui incendiu, ceea ce poate conduce la reduceri ale primei de asigurare

Asigurarea conformitatii: Termografia poate fi utilizata pentru a asigura conformitatea cu reglementarile si standardele de securitate si siguranta. Prin respectarea acestor norme, compania poate reduce riscul de incidente sau daune care ar putea genera reclamatii de asigurare, ceea ce poate duce la costuri mai mici pe termen lung.

Gestionarea riscurilor de deteriorare a proprietatii: Prin identificarea si remedierea problemelor termice in echipamente si instalatii, termoviziunea poate ajuta la prevenirea deteriorarii acestora. Daca se minimizeaza riscul de deteriorare a proprietatii, compania poate negocia reduceri ale primelor de asigurare, deoarece riscul perceput este mai mic.

Evaluarea riscurilor: Termografia poate furniza informatii detaliate despre riscurile potentiale dintr-o proprietate sau dintr-un proces industrial. Companiile de asigurare pot utiliza aceste informatii pentru a evalua mai precis riscurile asociate si pentru a ajusta primele de asigurare in functie de gradul de expunere la aceste riscuri.