Industrial energy audit

Request

Offer

Please contact us. For any questions, comments or clarifications, we are at your disposal

Care sunt obligatiile

operatorilor economici?

Operatorii economici care consuma anual o cantitate de energie sub 1000 TEP pe an, cu exceptia IMM-urilor, sunt obligati sa intocmeasca la fiecare 4 ani un audit energetic industrial realizat de o persoana fizica sau juridica autorizata in conditiile legii si care sta la baza stabilirii si aplicării măsurilor de imbunatatire a eficientei energetice.

Economic operators that annually consume an amount of energy over 1000 TEP are obliged to perform an energy audit once every 4 years on the entire energy consumption outline; the audit is developed by the energy auditor and is the basis for the establishment and application of energy efficiency improvement measures.

Our specialists have the necessary expertise for the following

tipuri de audit energetic industrial

Energy audit

Thermal energy audit

Complex energy audit

Presentation

materials

Aveti la indemana oricand prezentarea serviciilor de audit oferite de Quartz Matrix

Suggested measures

energy efficiency

In order to identify solutions to reduce consumption and energy costs, our specialists have carried out various industrial energy audits aimed at installations with the highest energy efficiency potential. Following the performance of complex measurements/calculations/analyses in the key points of the distribution and consumption system, the identified solutions were embodied in the Plan of measures and actions for increasing energy efficiency. The companies that created and implemented such plans are:

Over

400 audits

Dedicated specialists for carrying out the industrial energy audit

10 specialists

3 ANRE authorized energy auditors

Department of Energy Efficiency, Ministry of Energy - for electroenergetic audit, thermoenergetic audit and complex energy audit

8 ANRE authorized energy engineers

With grades II A, II B, III B, IV A and IV B

Authorized Ministry of Energy 0161/2022

Energy auditor

Authorized legal entity ANRE class II complex no. QM 0045/2023

Company providing energy services for industries

Authorization 0038/2021

Accredited company as Energy Auditor/ Energy Manager, authorized in the context of Law 121/2014 on energy efficiency.

Cadrul

legal

Energy audits are carried out in accordance with the requirements of the Energy Efficiency Law no. 121 of 18.07.2014, with additions to Law 160 of 26.07.2016 adopted by the Romanian Parliament.

The activities carried out are in accordance with the provisions of the guide for the development of energy audits, approved by the decision of the president of the National Energy Regulatory Authority (ANRE).

Benefits

audit energetic industrial alaturi de noi

You benefit from a clear image of energy efficiency on energy segments (electric, thermal, compressed air) for the company's internal processes.

The main opportunities to reduce consumption are identified and are recommended the technologies and equipment for implementing these measures.

It is attained a whole and clear image of energy efficiency for the company’s internal processes.

The losses on the input / production, distribution and consumption areas are highlighted

Quantifying energy saving costs.

The categories of measures are economically substantiated, based on the estimated effects and the recovery time of the investment.

Carrying out stages

industrial energy audit

Establishing by mutual agreement with the beneficiary the outline of the analyzed energy balance, focused on areas with potential for energy efficiency and consumption reduction. Identification of the main energy flows used (electricity, methane gas, compressed air, water, steam, etc.)

Identification of the main energy flows used (electricity, methane gas, compressed air, water, steam, etc.)

Detailed inspection of all installations subject to audit, in order to establish the degree of wear of the equipment

Identification of the technical characteristics of the main aggregates and installations

Collecting specific data for each type of installation and information, in order to identify the most efficient technical solutions for energy efficiency and reduction of energy consumption

Establishing the diagrams and measuring points where the measuring instruments will be mounted in order to obtain the most accurate information on the condition of the installations and equipment

Energy measurements in the key points of the distribution and consumption system

Calculations and preparation of a real energy balance to highlight the following

- Consumption and loss diagrams

- List of equipment with substandard operation and loss areas

- Identification of energetically and technologically underperforming machinery and equipment

- Highlighting the main opportunities for energy efficiency and intervention to reduce energy consumption in the final product

Contact our specialists and carry out the energy efficiency plan for your company.

Drafting a plan of measures and actions to increase energy efficiency that contains:

- Synthesis of the analysis report with the main energy characteristics attesting to the current energy efficiency of the audited installation

- Detailed presentation of the packages of technical measures proposed for energy modernization

- Input data for the economic analysis of the expected technical measures

- The cost of implementing the expected energy efficiency solutions

- The amortization period of the proposed investment

What we provide following the industrial energy audit

industrial ?

- Defining the contour

- The technical characteristics of the main aggregates and installations in the contour

- Technological flow scheme

- Establishing the reference unit associated with the balance sheet (hour, cycle, year, charge, ton)

- Brief presentation of the technological process (technical and economic parameters)

- Used measuring devices, technical characteristics and accuracy class

- Scheme and measurement points

- Measurement sheet

- Balance sheet equation

- Calculation of balance sheet components (analytical expressions, calculation formulas)

- Balance sheet chart and Sankey diagram

- Balance sheet analysis (comparison of useful and wastage components with those achieved in similar processes and installations regarding layout, reception, approval, known internally, externally and in the literature)

- Optimized balance sheet

- Measures and actions plan to increase energy efficiency

- Calculation of the economic efficiency of the main established measures

- Impact calculation of the elements on the environment

Find out about the main opportunities to reduce

consumption

Keep track of the accounting of electricity flows

Energy audit

Electric power audit benefits

- Measurement of the amounts of active electrical energy entered into the circuit during the reference period

- Determination by calculation, based on power measuring devices or simultaneous measurement of current, voltage and power factor, of energy losses

- Establishing the amounts of energy absorbed usefully

Identify the first signs of malfunction

Thermal energy audit

Thermal energy audit benefits

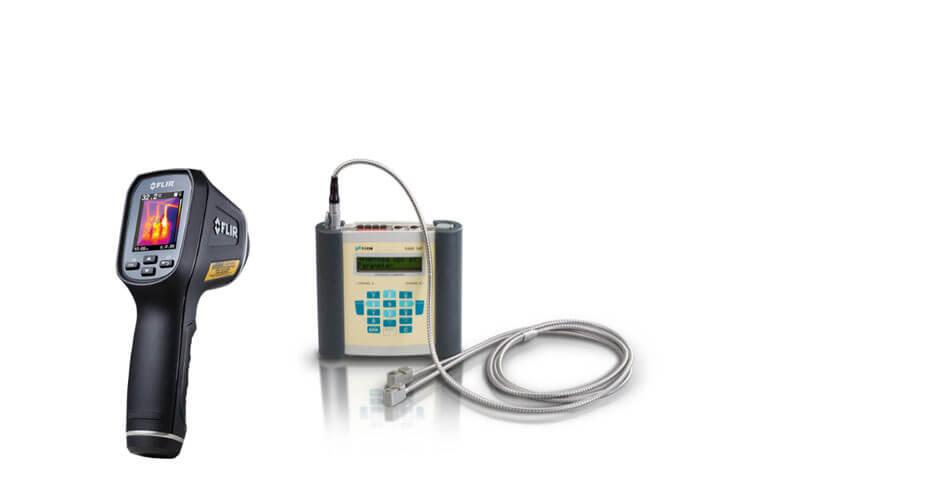

- Measurement of surface temperatures of equipment and distribution pipes of thermal agents, with a thermal imaging camera

- Checking condensation pots, heat exchangers

- Analysis of the combustion gases discharged at the chimney to establish the quality of the combustion process and the efficiency of fuel use

- Quick identification of contact problems in electrical installations (loose screws, improper crimping of cables, the appearance of the oxide layer between the materials that make the electrical connection, internal defects of the cables), through thermographic analysis

Benefit from a broad, clear and realistic "radiography" of energy consumption

Complex energy audit

Benefits of complex energy audit

- The analysis of energy balances will lead to: locating energy losses, determining their causes and classifying them, as well as establishing the measures that must be applied to optimize the technical-economic indicators

- The analysis will highlight all reusable energy resources, highlighting them by category and energy potential

- The central objective of the energy audit is to substantiate and quantify, through cost-benefit analysis, feasible solutions to increase energy efficiency

Measuring

devices

The correct application of procedures for increasing energy efficiency implies in-depth knowledge of the specifics of the activity carried out in an established outline. In this sense, for the precise determination of energy flows entering and exiting a given contour, the latest portable measuring and data acquisition equipment are used. These high-performance equipment offer the possibility of performing a qualitative and quantitative analysis of the energy supply of the activities carried out in an outline and, respectively, provide effective information with the role of identifying, locating and preventing problems in energy installations.